By Etrit Demaj

On this page

Sign up to our newsletter

Subscribe to receive the latest blog posts to your inbox every week.

By subscribing you agree to with our Privacy Policy.

Originally published in Retail & Restaurant Facility Business Magazine

Retail operators have long accepted reactive maintenance as the cost of doing business.

When equipment breaks, facility teams respond, often at high cost and with little warning. But this break-fix cycle no longer works in today’s environment of shrinking margins, energy mandates, and rising customer expectations.

A growing number of multi-site operators are shifting to a proactive, tech-enabled maintenance model that prevents problems, instead of waiting for them to arise. This approach turns building systems into assets, reducing costs, extending equipment life and improving the in-store experience.

The Real Cost of “Business as Usual”

Reactive maintenance isn’t just inconvenient, it’s expensive. Unplanned downtime disrupts operations and affects sales. Technicians are diverted from their planned work. And equipment that has been run to the point of failure often requires replacement.

One national, Fortune 100 retailer, managing more than 4,800 stores, faced these problems on a massive scale. Fragmented and vendor-locked building systems made centralized portfolio oversight impossible. Without visibility into HVAC, lighting or energy use, the company missed preventable issues, including lights left on overnight and heating and cooling systems running simultaneously. These overlooked inefficiencies cost retailers millions each year.

Without reliable data, maintenance becomes a guessing game. At scale, those guesses are costly.

Turning Data Into Operational Advantage

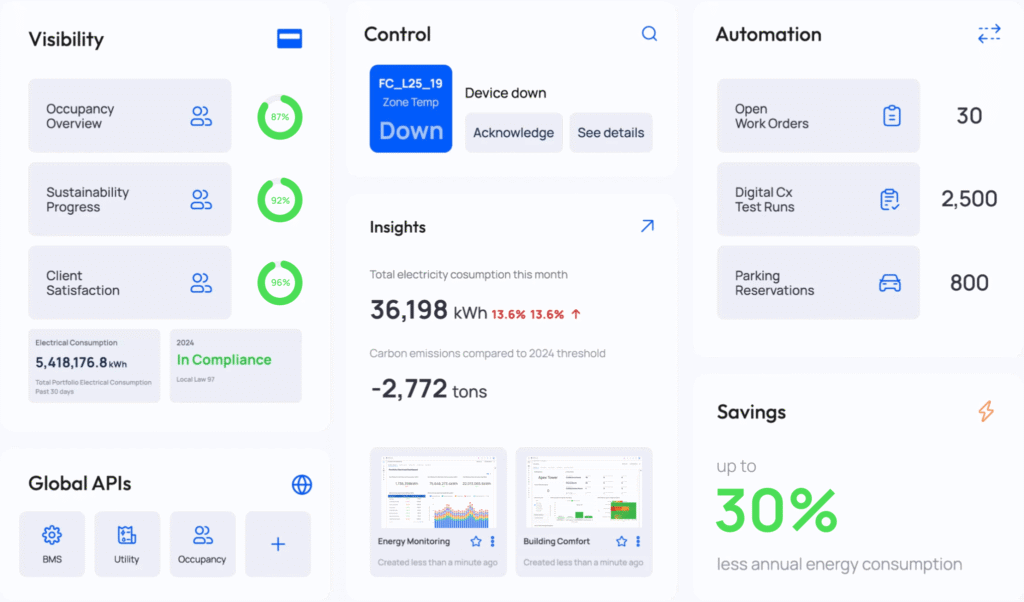

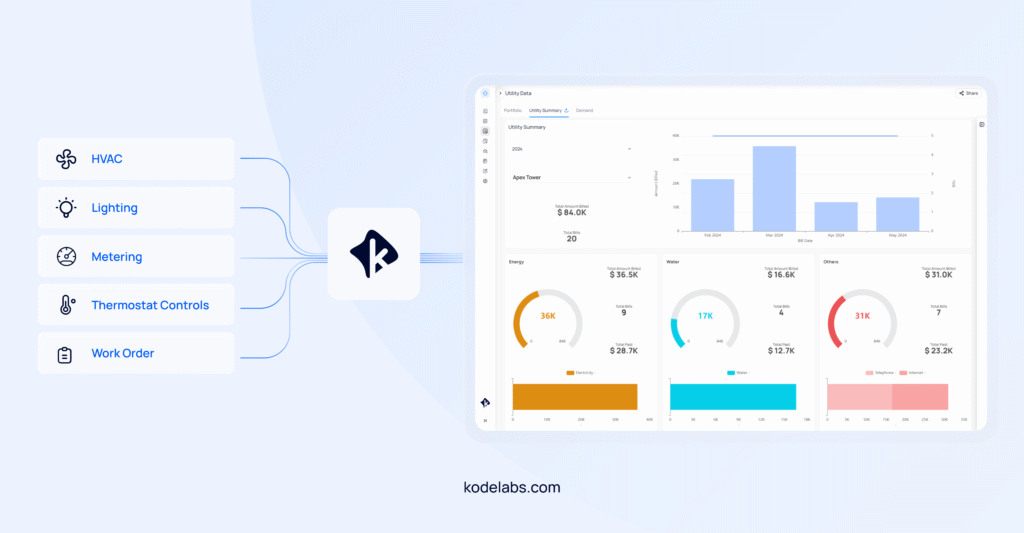

Smart building platforms provide an efficient, sophisticated way forward. Cloud-based systems integrate with legacy infrastructure and deliver real-time insight into performance. Multi-site operators gain centralized control over energy use, equipment health and diagnostics.

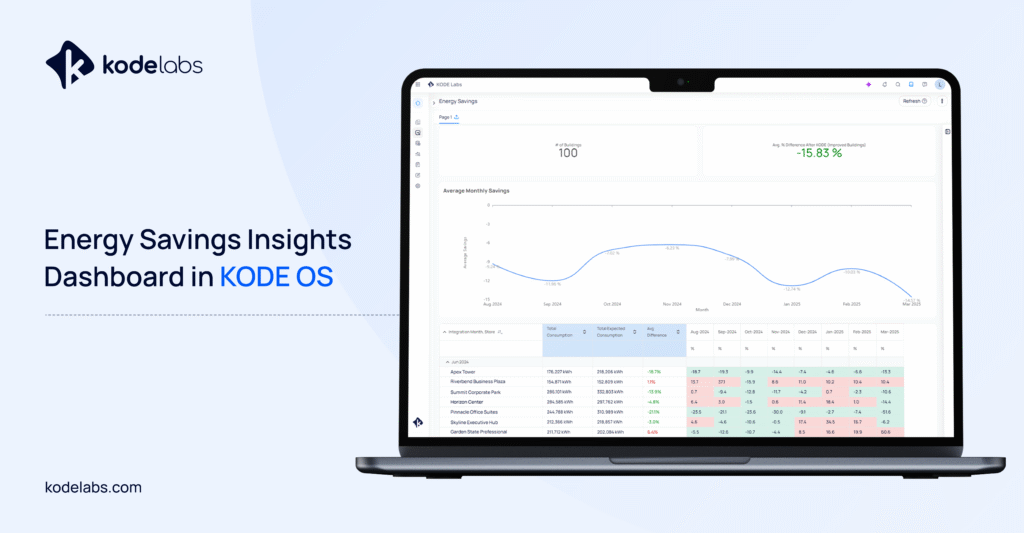

The 4,800-store retailer, for example, piloted smart upgrades in 20 locations, then scaled those upgrades to more than 1,000 stores. With unified data, the company reduced HVAC service calls by 1-2 per store per season. It also eliminated what are known as “ghost” overrides, manual changes to system routines that no one remembers making but everyone pays for.

A third-party analysis projected $6 million to $7 million in annual savings if the retailer expanded the system portfolio-wide, driven by energy reductions, fewer truck rolls (the dispatch of service professionals to evaluate a system problem in person), and better uptime.

5 Signs Your Maintenance Program Is Ready for a Smart Systems Upgrade

Is your facilities team constantly in reactive mode? Here are five tell-tale signs it’s time to modernize your maintenance strategy.

- You’re still relying on “break-fi x” responses: If most maintenance happens only after something breaks, you’re likely dealing with higher costs, more downtime and accelerated equipment wear.

- You have no centralized visibility into your building systems: Disparate HVAC, lighting and refrigeration systems installed over time can create data silos and leave you blind to performance issues across your portfolio.

- You’re spending time and money on problems that could be prevented: From heating and cooling running simultaneously, to lights left on overnight, preventable inefficiencies often go undetected, driving higher costs.

- You can’t compare performance across locations: Without a unified data layer, it’s difficult to benchmark energy use or identify outlier stores that need attention.

- You’re missing out on government rebates and incentives: Modern platforms not only reduce energy costs but also help operators qualify for state-level rebates that can offset a portion of implementation costs.

Unifying Data Across Systems

Central to this shift is the ability to unify data across disparate systems. Most retail environments operate with a patchwork of technologies — HVAC, lighting, refrigeration — installed over time and functioning independently. Integrating those systems into a single digital platform creates a comprehensive, real-time

view of building performance.

This unified data layer eliminates silos and brings clarity to operations. Facilities leaders can benchmark performance across locations, identify outliers and target interventions where they will deliver the most impact. For the Fortune 100 retailer, normalizing data across more than 1,000 stores unlocked visibility that was previously out of reach. The team could compare energy use, detect excessive runtimes and flag underperforming assets in minutes.

Standardizing the way companies collect, visualize and act upon data transforms disjointed systems into modern, insight-driven maintenance environments.

Prioritizing Action Over Alerts

Smart systems do more than send alerts, they provide prioritized guidance. Instead of reacting to complaints, facility teams spot issues early and solve them fast. For example, heating systems can go through digital commissioning reviews each fall to catch problems before cold weather hits. This early intervention minimizes downtime, reduces emergency calls and extends equipment life.

Mobile access supports this speed. Technicians can review diagnostics, trigger repairs and resolve problems, all from a phone or tablet anywhere with internet connectivity or a cell signal. Regional managers can deploy mass updates portfolio-wide, cutting time and cost. What once took weeks now takes minutes.

Scaling Without Starting Over

Many operators assume upgrades mean replacing existing systems. Today’s smart platforms challenge that assumption. Most layer onto legacy systems, making upgrades affordable and scalable. The Fortune 100 retailer mentioned above adopted this strategy and last year announced a nationwide initiative to unify its energy systems while maintaining existing infrastructure. The company prioritized scalability, reliability, and integration, proving that smart tech can deliver modern results without full-scale replacements.

Operators can roll out changes in phases, standardize performance, and deliver consistent results, without overhauling entire systems.

Rebates and Long Term ROI

Smart systems don’t just reduce costs, they also unlock utility incentives. States including Michigan, Illinois and Massachusetts have offered rebates that cover a portion of implementation costs.

While it’s unclear how new federal legislation will affect those rebate programs, state-level programs and policies are expected to continue, helping FM teams reclaim modernization expenses and improve ROI.

Facilities as a Strategic Asset

Operators have traditionally seen facilities as cost centers. But with better tools, they become drivers of business value.

Smart systems help reduce energy consumption, meet sustainability goals and improve in-store comfort, all of which support customer experience and business performance.

At the national retailer, FM teams moved beyond troubleshooting. With access to actionable data, they helped prioritize capital spending and supported ESG reporting. They became partners in planning/performance.

The Bottom Line

Retailers and restaurants face complex operating challenges. Moving from reactive to proactive maintenance creates a smarter, more resilient foundation.

The right technology offers more than efficiency, it delivers control, consistency and insight.

Smart systems aren’t just tools; they represent a new maintenance playbook. Operators that embrace it will stay ahead, operationally and competitively.