On this page

Sign up to our newsletter

Subscribe to receive the latest blog posts to your inbox every week.

By subscribing you agree to with our Privacy Policy.

For decades, building operators have wrestled with alarms. A single fault in HVAC or lighting could cascade into dozens, even hundreds, of alerts across the system. This “alarm fatigue” leads to inefficiency, slow response, costly mistakes and unhappy occupiers. Operators spent more time deciphering noise than solving problems.

The industry is now shifting away from this reactive alarm-based model toward a more intelligent approach: incident-driven fault management. Instead of treating every alarm as isolated, incidents bundle related alarms, highlight the root cause, and guide resolution.

The result isn’t just operational clarity and technical improvement, but rather a new way of driving measurable impact on Net Operating Income (NOI) across energy, maintenance, and operations.

Why Incidents, Not Alarms?

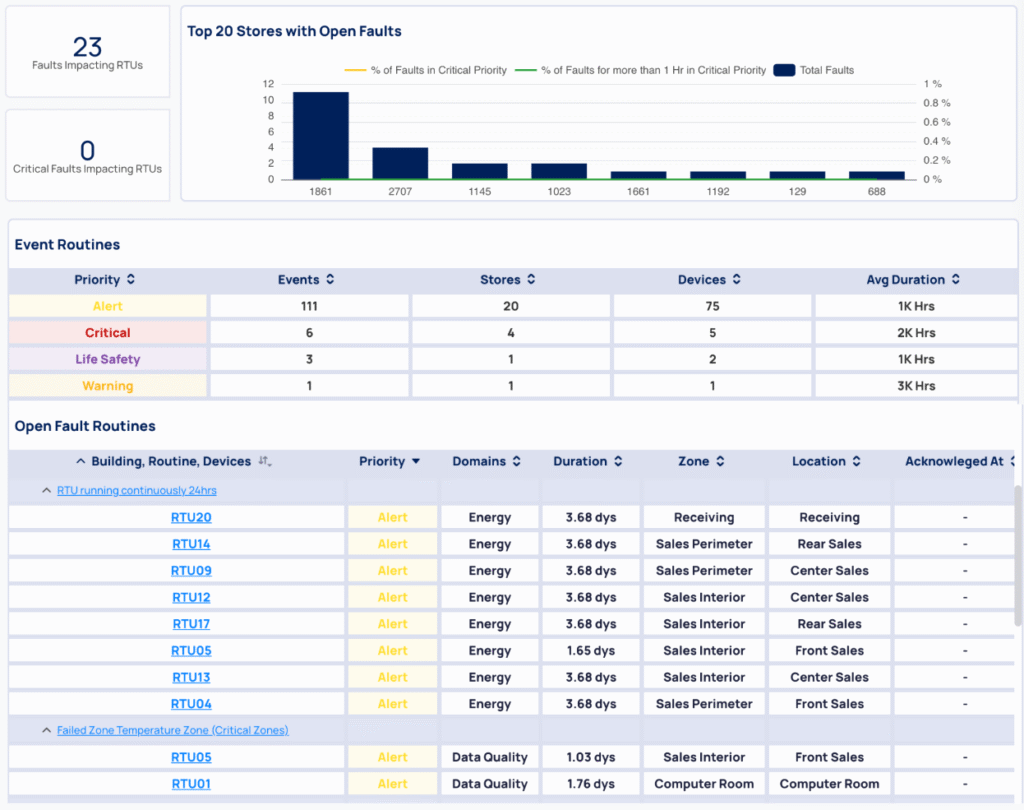

Traditional alarms overwhelm teams with noise, forcing operators to comb through alerts that often repeat or misrepresent the real problem. By contrast, incidents:

- Consolidate hundreds of alarms into a handful of actionable cases.

- Highlight the root cause, not just the symptoms.

- Prioritize issues based on impact, so teams focus effort where it matters most.

This shift represents a move from reactive firefighting to proactive management. Instead of drowning in alerts, operators gain a clear, prioritized path to resolution. And when paired with AI, this shift doesn’t just simplify operations, it transforms fault management into a direct financial lever for ROI.

AI as an NOI Multiplier

AI enhances this shift by transforming incidents into actionable intelligence. With AI, fault management becomes:

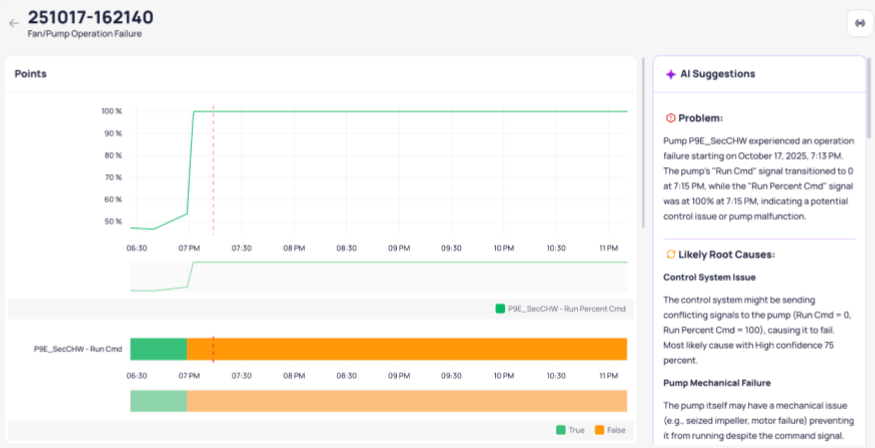

Faster: Instead of operators manually piecing together logs and alerts, AI scans fault data in real-time, summarizes the problem, and presents a clear diagnostic. What once took hours, even days, of investigation is condensed in seconds, accelerating response times.

Smarter: AI cross references fault patterns with historical data, equipment libraries, and contextual inputs (like occupancy or weather). This enables it to suggest the likely root cause, for example a drifting sensor versus a stuck damper, so teams resolve the actual issue, not just the symptom.

Focused: AI assigns priority by assessing impact: energy waste, asset damage potential, or comfort risk. Instead of treating all incidents equally, it directs operators towards the ones that deliver the greatest NOI upside if fixed first.

This turns fault management from a reactive cost center into a predictive margin enhancer.

Turning Faults into Savings (and NOI Uplift)

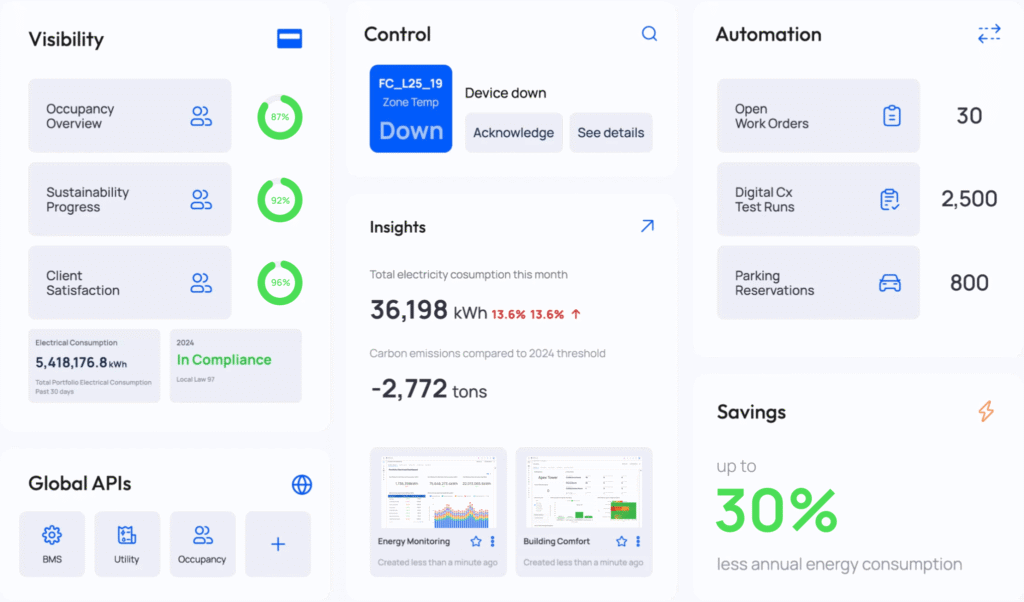

The financial impact of smarter fault management is clear. Each area of efficiency directly improves NOI by lowering operating expenses:

1. Operational Efficiency

- Consolidating alarms into incidents reduces noise by up to 90%.

- Operators spend less time sifting through alerts and more time resolving real issues.

NOI Impact: Streamlined workflows and reduced low-value tasks lead to up to 50% savings in operational costs, directly improving margins.

2. Maintenance Optimization

- Incidents can be automatically pushed as work orders, with histories tracked for audit and optimization.

- Predictive routines help prevent failures before they escalate.

- Technicians come prepared, reducing trial and error and preventing repeat visits.

NOI Impact: Fewer truck rolls, faster resolutions, and longer equipment lifespans generate up to 20% savings in maintenance costs.

3. Energy Savings

- Undetected faults like simultaneous heating/cooling, stuck dampers, or drifting sensors silently inflate energy bills.

- AI diagnostics surface these inefficiencies in real-time and prescribe corrective actions.

NOI Impact: Addressing hidden waste delivers up to 30% energy savings, slashing utility costs portfolio-wide.

Beyond NOI: Strategic Value

The benefits extend well beyond cost reductions:

- Occupant Comfort: Faster resolution of HVAC and lighting issues improves occupant satisfaction.

- ESG Compliance: Automated fault history and reporting support audit-ready sustainability disclosures.

- Portfolio Scalability: Routine libraries and no-code rule creation make it possible to standardize fault management across diverse assets.

From Burden to Value Driver

Fault management has long been seen as a necessary burden. The shift from alarms to incidents marks a turning point. By reducing noise, accelerating resolution, and eliminating inefficiencies, incident-driven fault management doesn’t just lower costs, it strengthens NOI and boosts asset value.

For owners and asset managers, smarter fault management is no longer just an operational tool. It’s a financial strategy that enhances NOI today and asset value tomorrow.

Want to learn more? Book a demo and see KODE OS in action